Back to products

Sanaky 200 GPD Water Purifier

৳ 48,000 Original price was: ৳ 48,000.৳ 45,000Current price is: ৳ 45,000.

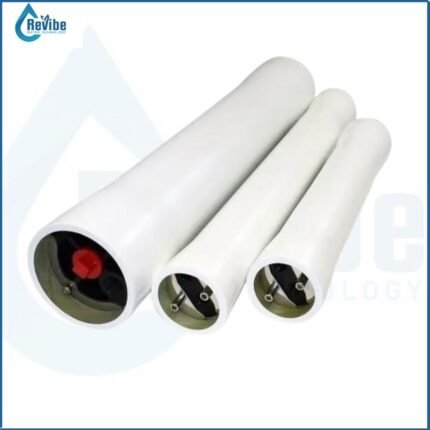

FRP Vessels

Description

FRP (Fiberglass Reinforced Plastic) vessels are pressure vessels constructed from a composite material of fiberglass and resin. They are widely used in various industries due to their strength, durability, and corrosion resistance. These vessels are engineered to withstand high pressures and harsh chemical environments, making them suitable for applications like water treatment, chemical storage, and filtration systems.

Key Features and Characteristics:

- Composite Material:

FRP vessels are made by combining a polymer matrix (typically resin) with fiberglass fibers, creating a strong and lightweight structure. - Corrosion Resistance:

A significant advantage of FRP is its resistance to corrosion, making it ideal for handling various chemicals and liquids without degradation. - Strength and Durability:

FRP vessels can withstand high pressures and are resistant to impact and wear, ensuring long-term performance. - Lightweight:

Compared to traditional materials like steel, FRP vessels are lighter, making them easier to handle, transport, and install. - Design Flexibility:

FRP allows for customized designs to meet specific application requirements, including different shapes, sizes, and pressure ratings. - Temperature Range:

FRP vessels typically have a temperature range of 1-49°C (34-120°F), but some specialized resins can handle higher temperatures. - Common Applications:

- Water Treatment: Used for filtration, softening, and other processes.

- Chemical Storage and Processing: Suitable for storing and handling various chemicals.

- Reverse Osmosis Systems: Commonly used as membrane housings.

- Industrial Processes: Employed in diverse industries like petroleum, food, and pharmaceutical.

- Operating Pressure:

While standard FRP vessels can handle pressures up to 100-150 psi, specific designs and materials can achieve higher pressures. - Vacuum Resistance:

FRP vessels should be protected from vacuum conditions with a vacuum breaker in the line. - Testing and Certification:

FRP vessels are often tested for pressure and cycle performance to ensure reliability and safety.

Examples of FRP Vessel Specifications:

- Shell Layer: Fiberglass.

- Maximum Test Pressure: 150 psi.

- Maximum Working Pressure: 100 psi.

- Temperature Range: 1-49°C (34-120°F).

- Maximum Vacuum: 5″Hg (127mm Hg).

- Minimum Burst Pressure: 600 psi.

- Cycle Testing: 250,000 cycles without leakage.

In conclusion, FRP vessels are versatile and reliable components in various industrial and water treatment applications, offering a combination of strength, corrosion resistance, and design flexibility.

| Model | Vessel Size | Capability | Opening | ||

| inch | mm | Liters | Top | Bottom | |

| GD-610 | 6×10 | 155×260 | 3.1 | 2.5″-NPSM | / |

| GD-613 | 6×13 | 155×335 | 4.6 | 2.5″-NPSM | / |

| GD-618 | 6×18 | 155×460 | 6.6 | 2.5″-NPSM | / |

| GD-629 | 6×29 | 155×740 | 11.1 | 2.5″-NPSM | / |

| GD-635 | 6×35 | 155×890 | 13.7 | 2.5″-NPSM | / |

| GD-813 | 8×13 | 205×335 | 7.7 | 2.5″-NPSM | / |

| GD-817 | 8×17 | 205×438 | 10.9 | 2.5″-NPSM | / |

| GD-835 | 8×35 | 205×890 | 25 | 2.5″-NPSM | / |

| GD-844 | 8×44 | 205×1130 | 32.1 | 2.5″-NPSM | / |

| GD-1035 | 10×35 | 255×905 | 38.4 | 2.5″-NPSM | / |

| GD-1044 | 10×44 | 255×1130 | 49.5 | 2.5″-NPSM | / |

| GD-1054 | 10×54 | 255×1380 | 63.3 | 2.5″-NPSM | / |

| GD-1248 | 12×48 | 300×1225 | 78.9 | 2.5″-NPSM | / |

| GD-1252 | 12×52 | 300×1340 | 85.8 | 2.5″-NPSM | / |

| GD-1265 | 12×65 | 300×1650 | 105.3 | 2.5″-NPSM | / |

| GD-1354 | 13×54 | 335×1398 | 104.5 | 2.5″-NPSM | / |

| GD-1465 | 14×65 | 355×1650 | 145.1 | 2.5″-NPSM | / |

| GD-1665/2.5″ | 16×65 | 400×1670 | 183 | 2.5″-NPSM | / |

| GD-1665/4″ | 16×65 | 400×1670 | 183 | 2.5″-NPSM | / |

| GD-1865/4″ | 18×65 | 450×1670 | 253 | 4″-8UN | / |

| GD-2169/4″ | 21×69 | 530×1750 | 316 | 4″-8UN | / |

| GD-2169/4″-4″ | 21×69 | 530×1590 | 316 | 4″-8UN | 4″-8UN |

| GD-2472/4″ | 24×72 | 600×1850 | 415 | 4″-8UN | / |

| GD-2472/4″-4″ | 24×72 | 600×1850 | 415 | 4″-8UN | 4″-8UN |

| GD-2487/4″-4″ | 24×87 | 600×2200 | 510 | 4″-8UN | 4″-8UN |

| GD-3072/4″ | 30×72 | 750×1850 | 640 | 4″-8UN | / |

| GD-3072/4″-4″ | 30×72 | 750×1850 | 640 | 4″-8UN | 4″-8UN |

| GD-3087/4″-4″ | 30×87 | 750×2200 | 782 | 4″-8UN | 4″-8UN |

| GD-3672/4″-4″ | 36×72 | 900×1850 | 850 | 4″-8UN | 4″-8UN |

| GD-3694/6″F-6″F | 36×94 | 900×2400 | 1205 | 6″-flange | 6″-flange |

| GD-4072/4″ | 40×72 | 1000×1850 | 1050 | 4″-8UN | / |

| GD-4072/4″-4″ | 40×72 | 1000×1850 | 1050 | 4″-8UN | 4″-8UN |

| GD-4272/6″F-6″F | 42×72 | 1070×1850 | 1100 | 6″-flange | 6″-flange |

| GD-4094/6″F-6″F | 40×94 | 1000×2400 | 1370 | 6″-flange | 6″-flange |

| GD-4294/6″F-6″F | 42×94 | 1070×2400 | 1465 | 6″-flange | 6″-flange |

| GD-4872/6″F-6″F | 48×72 | 1200×1850 | 1308 | 6″-flange | 6″-flange |

| GD-4894/6″F-6″F | 48×94 | 1200×2400 | 1909 | 6″-flange | 6″-flange |

| GD-6094/6″F-6″F | 60×94 | 1500×2400 | 2688 | 6″-flange | 6″-flange |

| GD-6383/6″F-6″F | 63×83 | 1600×2100 | 2580 | 6″-flange | 6″-flange |

| GD-6394/6″F-6″F | 63×94 | 1600×2400 | 3150 | 6″-flange | 6″-flange |

| GD-7294/6″F-6″F | 72×94 | 1800×2400 | 3950 | 6″-flange | 6″-flange |